- Home

- About

- Products

-

-

- Plastic Bottles

- HDPE Boston Bottles

- HDPE Dallas Bottles

- HDPE Flask Bottles

- HDPE Standard Bottles

- HDPE Wide Neck Bottles

- LDPE Boston & Standard Bottles

- LDPE Dallas Bottles

- LDPE Flask Bottles

- LDPE Squeezy Bottles

- PET Beverage Bottles

- PET Boston Fluted Bottles

- PET Cosmo Bottles

- PET Foaming Bottles

- PET Squeezy Bottles

- PET Standard Bottles

- Pumps

- Plastic Bottles

-

- News

- Contact

Guide to Safe Skincare and Cosmetic Packaging

- 12 October 2023

- By: Allison Davies

If you choose the wrong cosmetic packaging, your customers may not experience the full effectiveness of the product.

When packaging skincare products, there are some things that you must take into account:

- Safety of the product

- Appearance and aesthetic appeal to your customer

- Sustainability, especially if your brand is eco friendly

- Functionality; does the tube squeeze, is the dispensing pump able to manage the thick creams?

Probably the most important is safety of the product. In NZ, the environmental protection agency (EPA) law says that the packaging must:

- Not leak when it’s filled and closed

- Not leak when the product has been opened and then reclosed

- Not react with the contents of the package

While this seems very basic, depending on what your product contains, it could actually be complex. For example, oil is notorious for not staying in the container and creeping out of the seal. And, different ingredients react with different packaging. Even ‘natural’ ingredients can have reactions; lemon, for example, is acidic and can degrade some plastics or metals.

When choosing wholesale cosmetic packaging supplies, you need to think about the following things.

Ability to Block Light

Some skincare products are sensitive to light. Think of retinoids, salicylic acid, essential oils, AHA’s, fruit enzymes, and benzoyl peroxide. This is why often skincare packaging is opaque or serums are in black or brown glass bottles.

Lessening Exposure to Air

Vitamin C, vitamin E, and retinol can degrade very quickly when exposed to air. Most products that contain these ingredients won’t be effective for long once they are opened. This is why pump bottles can be useful as they limit the amount of air the product is exposed to. Oils can go rancid very quickly- give it a sniff if you’re unsure.

Also, fingers can introduce bacteria to a product, so pots of moisturiser can be unhygienic. Consider squeezy bottles or tubes rather than pots, and dispensers rather than droppers.

Managing Heat

Extreme heat can damage skincare products. Imagine being left in a car on a hot day, where temperatures can rise above 50 degrees Celsius. While products have stability testing and shelf life integrity testing, some products degrade faster when warm, and heat also encourages bacteria growth (fingers in pots again). Blended oils and waters can separate, which should be able to be mixed again by shaking.

Extreme cold/ freezing can also cause mixtures to separate and denature enzymes.

Acids and Alkaline Products Can Corrode

A number of skin products can be acidic or alkaline/ basic. These can react with metals and some plastics if not coated with a protective barrier., causing degradation and corrosion. This means that the product is ruined.

Instead, glass, PET and polypropylene plastic is non-reactive.

Physical Safety

Metal containers can dent and corrode. Glass containers can break and chip. Plastic is highly versatile and very resistant to physical damage. Glass can be appropriate in some cases but avoid for products designed for use in the shower or used around kids.

Plastic is far safer in terms of breakages and impact falls.

What’s The Best Packaging for Your Skincare Product?

The answer is different for each product and each brand. There’s no easy answer, you have to research what’s in each product and if it has special packaging requirements.

Heat and Cold Sensitive Products

While you can’t stop your customers from leaving products in hot cars, you can supply packaging that does help to insulate the product. These containers are made from virgin polypropylene, which is recyclable once the product is finished. It’s BPA free, and highly resistant to acids and other solvents or chemicals. These are all white, so provide stability for light-sensitive products.

- Double wall cosmetic jars 5gm

- Double wall cosmetic jars 10gm

- Double wall cosmetic jars 20gm

- Double wall cosmetic jars 30gm

- Double wall cosmetic jars 50gm

- Double wall cosmetic jars 100gm

Light and UV Sensitive Products

Using white packaging means no risk of light and UV damaging your product. These cosmetic pots with lids are made from stable, strong, and 100% recyclable polypropylene.

- Round cosmetic pot 10g/7ml

- Round cosmetic pot 20g/15ml

- Round cosmetic pot 30g/25ml

- Round cosmetic pot 50g/45ml

- Round cosmetic pot 100g/90ml

- Round cosmetic pot 150g/135ml

- Round cosmetic pot 200g/180ml

- Round cosmetic pot 250g/220ml

- Round cosmetic pot 300g/260ml

Non-Reactive Plastic

Our range of clear plastic pots are made from PET plastic (sizes 100ml – 250ml) and polystyrene (sizes 5gm-50gm). This plastic is non-reactive, doesn’t contain BPA, and the lids come with a pressure seal (sizes 100ml-250ml), so there’s no spillage in transit. The clear design is elegant and allows the consumer to see at a glance how much product they have left.

- Cosmetic Pot Clear 5gm

- Cosmetic Pot Clear 10gm

- Cosmetic Pot Clear 15gm

- Cosmetic Pot Clear 20gm

- Cosmetic Pot Clear 30gm

- Cosmetic Pot Clear 50gm

- Cosmetic Pot PET 100ml

- Cosmetic Pot PET 150ml

- Cosmetic Pot PET 200ml

- Cosmetic Pot PET 250ml

Air and Bacteria Exposure

These HDPE bottles are stable, resistant to plastic leaching, and can have pump dispensers or disc caps attached. This means less air exposure and no fingers in the product.

- Dallas HDPE Bottle 60ml 24/410

- Dallas HDPE Bottle 100ml 24/410

- Dallas HDPE Bottle 250ml 24/410

- Dallas HDPE Bottle 500ml 28/410

- Dallas HDPE Bottle 1L 28/410

- Cosmetic Pumps

- Disc Caps

Still Looking For the Best Cosmetic Packaging in NZ?

If you are unsure what the best option is- and we know, the options are endless- contact us on 09 448 5960. We’ve had years of experience as wholesale cosmetic packaging suppliers here in New Zealand. We know what your customers like, and what your product needs in order to stay safe and effective. We can help you find the best packaging for your cosmetics and skincare.

More News

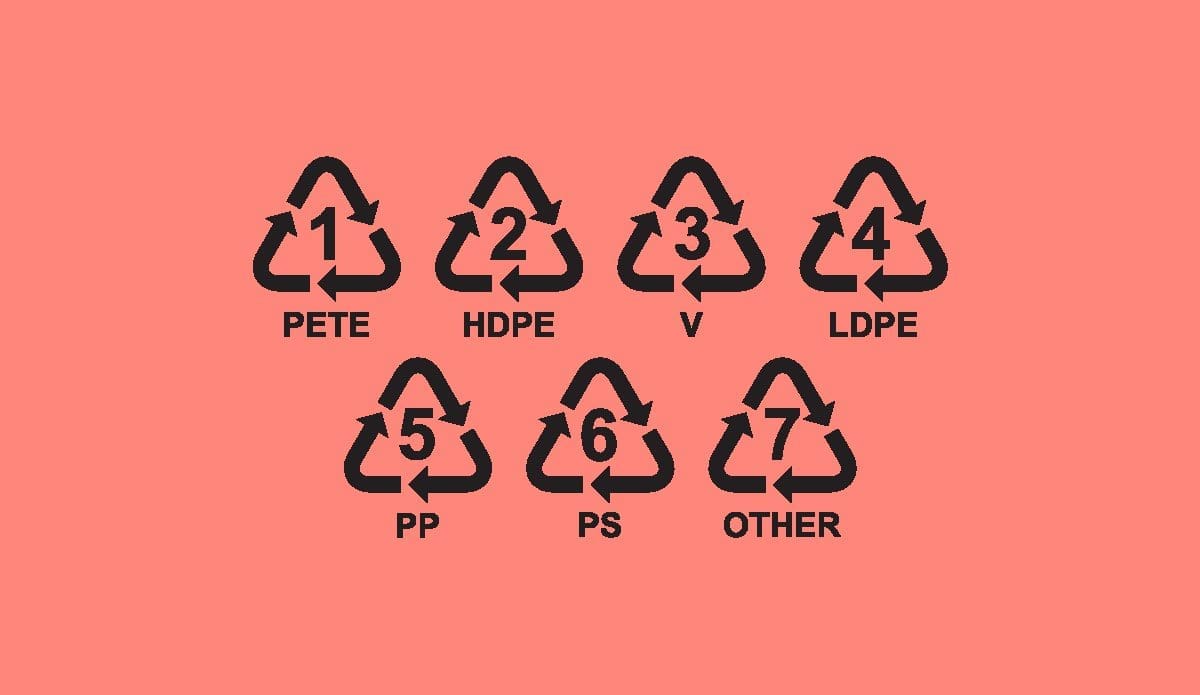

You have probably heard about plastic recycling number. But what do these numbers mean for you and your New Zealand business?

There are seven different groups that plastics can belong to. Some are recyclable and some less so.